Tecno Fast HOME / What is it

We deliver sustainable space solutions to improve the lives of people through innovation and design. We believe in the value of time, respect for the environment and the importance of efficiency and quality.

Triple ISO certification in environment, quality, safety and occupational health

Tecno Fast, a leading company in the modular sector, boasts more than 26 years of experience and more than 3,000,000 constructed squared metres, and is synonymous with efficiency and confidence.

Transparency, with no hidden extras and an initial estimate from the beginning, without any variations.

Our plant favours productive efficiency, control over the cost of materials and the planning of work on site.

An Ecofriendly model in which 75% of production is through solar power. Reducing environmental impact.

QUALITY

Triple ISO certification in environment, quality, safety and occupational health

SUPPORT AND WARRANTY

Tecno Fast, a leading company in the modular sector, boasts more than 26 years of experience and more than 3,000,000 constructed squared metres, and is synonymous with efficiency and confidence.

FIXED ESTIMATES

Transparency, with no hidden extras and an initial estimate from the beginning, without any variations.

100% OPERATIONAL

AUTOMATIZED ROBOTIC PLANT

Our plant favours productive efficiency, control over the cost of materials and the planning of work on site.

SUSTAINABILITY

An Ecofriendly model in which 75% of production is through solar power. Reducing environmental impact.

·Modular Assadi houses and Tiny Cabins are made based on a steel cage structure that provides resistance and ductility necessary to resist the seismic forces according to the regulations in force. The wall, floor and ceiling panels provide greater residential comfort and will be designed to resist use, wind and snow according to regulations in force.

· They weigh approximately 200 kg / m2, which is a lot less than those of a traditional home made of reinforced concrete or masonry at 1000 to 1500 kg / m2. As a result, the seismic stress, which is proportionate to the weight of the construction, is up to five times less.

· The resistant structures have been designed for a seismic zone 3 according to the NCh433 official Chilean regulations in force and Supreme Decree No 61, the most demanding zone for anti-seismic construction.

· Assadi Modular Houses, Tecno Kits and Tiny Cabins are F30 fire-resistant, complying with the General Construction and Urbanism Ordinance of Chile

· Assadi Modular Houses, Tecno Kits and Tiny Cabins use impregnated anti-termite OSB construction panels.

The Smartpanel has an anti-termite and anti-fungal metabolic inhibitor that affects termites and fungi but not humans.

· The modular solutions offered by Tenco Fast – Assadi Modular Houses, Tecno Kits and Tiny Cabins – guarantee the construction materials and systems used in roofing complexes, perimeter walls and ventilated lower floors. They thus comply with Zones 6 and 7 thermal zoning, which correspond to the most severe geographical locations as defined by the General Construction and Urbanism Ordinance of Chile.

· To comply with Zone 7 thermal zoning, the roofing must have at least 160mm of glass wool, the perimeter walls must have at least 80mm, and ventilated floors must have 140mm.

· To comply with Zone 6 thermal zoning, the roofing must have at least 140mm of glass wool, the perimeter walls must have at least 80mm, and ventilated floors must have 140mm.

The early incorporation of the automatization of the processes of integral manufacturing solutions has enabled us to offer our clients a product with the highest standards of design and quality, thus developing a unique installation in the region.

The early incorporation of the automatization of the processes of integral manufacturing solutions has enabled us to offer our clients a product with the highest standards of design and quality, thus developing a unique installation in the region.

Modular construction can optimize delivery times by 50% thanks to the process of online manufacturing carried out at the plant.

• As it is a process carried out in the plant, there is greater quality control than that reaIized on site.

• The production process enjoys ISO 9001 certification, unlike most conventional constructions.

• The higher level of training and specialization of employees enables their professional development.

• The modules must be constructed in a robust manner in order to bear the weights of the crane and their transfer. Each transfer is equivalent to subjecting a module to a magnitude 5 earthquake for the entirety of its transportation.

• Modular construction boasts greater thermal and acoustic insulation due to the need to duplicate walls and ceilings to generate vertical or horizontal unions between two or more units.

• Modular construction boasts greater thermal and acoustic insulation due to the need to duplicate walls and ceilings to generate vertical or horizontal unions between two or more units.

• Modular construction does not suffer from the problems of dampening or fracturing that occur with concrete or masonry.

• The construction area generates lower waste levels and energy costs, as well as less air, water and noise pollution

• Modular construction uses certified timber, which means that production is controlled and each tree cut down is replaced.

• Greater safety for staff, who are not exposed to extreme climactic conditions and temperatures for a long period of time.

• As modular construction is faster, it generates less of an impact on the construction site, as well as meaning drier and tidier works.

• Recyclable modular construction can be reassembled in a new location and thus become a project with the same objectives as the initial one, or even different ones.

• Modular construction can be easily relocated as the materials used in the process can be disassembled and reassembled in any convenient location.

• The constructed square metres of modular constructions can be expand or reduced according to requirements.

• One of the most versatile construction systems currently existing in the market, it can be installed in any environment or climactic condition.- One of the most versatile construction systems currently existing in the market, it can be installed in any environment or climactic condition.

Modular construction can optimize delivery times by 50% thanks to the process of online manufacturing carried out at the plant.

• As it is a process carried out in the plant, there is greater quality control than that reaIized on site.

• The production process enjoys ISO 9001 certification, unlike most conventional constructions.

• The higher level of training and specialization of employees enables their professional development.

• The modules must be constructed in a robust manner in order to bear the weights of the crane and their transfer. Each transfer is equivalent to subjecting a module to a magnitude 5 earthquake for the entirety of its transportation.

• Modular construction boasts greater thermal and acoustic insulation due to the need to duplicate walls and ceilings to generate vertical or horizontal unions between two or more units.

• The materials for modular construction are stored in warehouses or plants that avoid warping, dampening or other imperfections caused by keeping materials outdoors.

• Modular construction does not suffer from the problems of dampening or fracturing that occur with concrete or masonry.

• The construction area generates lower waste levels and energy costs, as well as less air, water and noise pollution

• Modular construction uses certified timber, which means that production is controlled and each tree cut down is replaced.

• Greater safety for staff, who are not exposed to extreme climactic conditions and temperatures for a long period of time.

• As modular construction is faster, it generates less of an impact on the construction site, as well as meaning drier and tidier works.

• Recyclable modular construction can be reassembled in a new location and thus become a project with the same objectives as the initial one, or even different ones.

• Modular construction can be easily relocated as the materials used in the process can be disassembled and reassembled in any convenient location.

• The constructed square metres of modular constructions can be expand or reduced according to requirements.

• One of the most versatile construction systems currently existing in the market, it can be installed in any environment or climactic condition.- One of the most versatile construction systems currently existing in the market, it can be installed in any environment or climactic condition.

Felipe Assadi is an architect who graduated from the Finis Terrae University in 1996 and also holds a Master’s in Architecture from the Pontifical Catholic University of Chile. In 1999, he received the Junior Promotion Prize by the Chilean Institute of Architects, awarded to the best architect in the country under thirty-five years of age.

He was the director of the School of Architecture at the Faculty of Architecture and Design in the Andres Bello University from 2008 to 2011, and has worked as a professor at the Finis Terrae University, the University of Talca, the University of Diego Portales, the Higher Institute of Technology of Monterrey in Mexico, the Autonomous University of San Luis Potosi in Mexico, the Pontifical Bolivarian University of Medellin in Colombia, the IUAV University of Venice in Italy and the University of the Andes in Colombia.

He has been invited to give conferences in Venezuela, Peru, Mexico, Puerto Rico, Costa Rica, Argentina, the United States, Italy and Spain. His work has been widely published in various countries in publications such as Wallpaper and Architectural Review in London, Arquitectura Viva and AV Monografías in Madrid, Architectural Record in New York, GA in Tokyo and both Domus and Casabella in Italy among others, as well as in specialist books worldwide.

He has participated in expositions in Barcelona, Pamplona, London, Quito, Tokyo and Santiago. His work has been carried out in Chile, Mexico, Guatemala, Peru, Puerto Rico, Venezuela, the United States, Ecuador and Colombia. To date, he has had four monographs; one in Chile, one in Spain, one in South Korea and one in Argentina. Since 2011, he has served as the Dean of the Faculty of Architecture and Design of the Finis Terrae University.

Arquitecto chileno, realizo sus estudios en la Pontificia Universidad Católica. A lo largo de su carrera ha combinado el trabajo académico con los proyectos de su estudio. Ha sido profesor de taller e impartido seminarios para pre y posgrado en diversas universidades en Chile y en el extranjero. Desde el 2003 ejerce como Decano de la facultad de Arquitectura, Arte y Diseño de la Universidad Diego Portales.

Su trabajo ha sido firmemente enraizado en la arquitectura moderna, donde ha desarrollado su propio lenguaje, temas y tipologías. Su obra ha sido reconocida internacionalmente, en numerosas publicaciones, ponencias y exhibiciones.

Entre los mayores reconocimientos, ha obtenido el Premio Borromini de Arquitectura en 2001 en la categoría de arquitectos menores de 40 años, en el año 2010 el Green Good Design con la Biblioteca Central Universidad Diego Portales y con esta misma obra el año 2011 el Holcim Awards, por el Barrio Universitario de Santiago (BUS) junto a Ricardo Abuauad en el año 2014 obtuvo el Premio Latinoamericano de Arquitectura Rogelio Salmona y el año 2015 el premio Aporte Institucional a la Arquitectura dado por la Asociación de Oficinas de Arquitectura de Chile.

Archiplan is a global consultancy provider in architecture, design and planning.

All of our projects have succeeded and they are distinguished by the enthusiasm, creativity and commitment with the environment, swift response, sensitivity and advanced knowledge in all aspects of aesthetics, culture, technology and commerce with which we meet every challenge that we undertake.

Deliver Sustainable Space Solutions to improve the lives of people through innovation and design.

We believe in the value of time, respect for the environment and the importance of efficiency and quality.

Deliver spaces of spaces that improve the lives of people.

Be a world leader of space solutions.

Deliver Sustainable Space Solutions to improve the lives of people through innovation and design.

We believe in the value of time, respect for the environment and the importance of efficiency and quality.

Deliver spaces of spaces that improve the lives of people.

Be a world leader of space solutions.

Tecno Fast is incorporated.

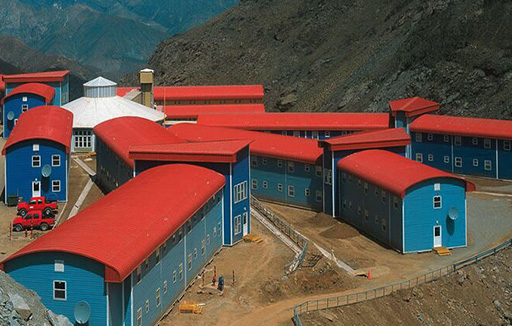

Manufacture, assembly and delivery of Tecno Fast’s first industrialised construction project: Doña Ines of Collahuasi, Chile (6,000 workers).

First international award from the Modular Building Institute (MBI) for the “Hotel del Inca” project in Collahuasi, Chile”.

The “Tecno Fast S.A.C. Peru” subsidiary is incorporated; the first international project is Antamina, Peru.

First place MBI prize for the Hotel Pelambres project.

Construction of the “Pelambres” (2001), “Minera Escondida” (2002) and “Spence” (2005) projects in Chile.

Rentals, a business department dedicated to the rental of spatial solutions, are created in Chile.

Tecno Fast Argentina (2008) is incorporated and the “Pascua Lama” project is constructed.

Construction of the “Caserones” project.

Tecno Fast Colombia S.A.S (Colombia) and Tecno Fast Modulos Do Brasil Ltda. (Brazil) are incorporated, focussing on the rental of spatial solutions in these markets. Construction of the “Minera Escondida OGP1” and “Nueva Etapa Doña Ines de Collahuasi” projects.

Acquisition of ATCO’s stake by the Inder Group (a holding controlled by Jose Luis, Barbara and Sebastian del Rio Goudie), in association with Cristian Goldberg Valenzuela and Cristian Concha Soffia.

Construction of projects “Minera Escondida OGP1” and “Nueva etapa Doña Ines de Collahuasi” in Chile.

The Tecno Fast Home line of products is created in Chile.

TheTecno Fast Village line of products is created with the first hotel in Chillepin, Chile.

Construction of the “Hospital del Salvador” in Chile.

Construction of the first six-floor modular constructions for the “Los Bronces” project.

Automatization of the construction and manifacturing process at the plant in Lampa, Chile.

Creation of the Tiny Cabin line in Chile.

Modular Building Institute prizes for Tiny Cabin, the El Tambo camp, and our institutional video.

Tecno Fast is recognized as one of the best companies in Chile and Tecno Kit is launched.

Tecno Fast also acquires Triumph, a leading modular solutions company from New England, USA.

We deliver last technology solutions in spaces to live and work, in record time with bounded costs and TECNO FAST backup.

Santiago

Puerto Varas

Maitencillo

Enviamos un mensaje !